The Mercedes-AMG One is the second Mercedes supercar to be produced outside Germany after the SLR McLaren. It will be assembled in Coventry and the engine is produced in Brixworth.

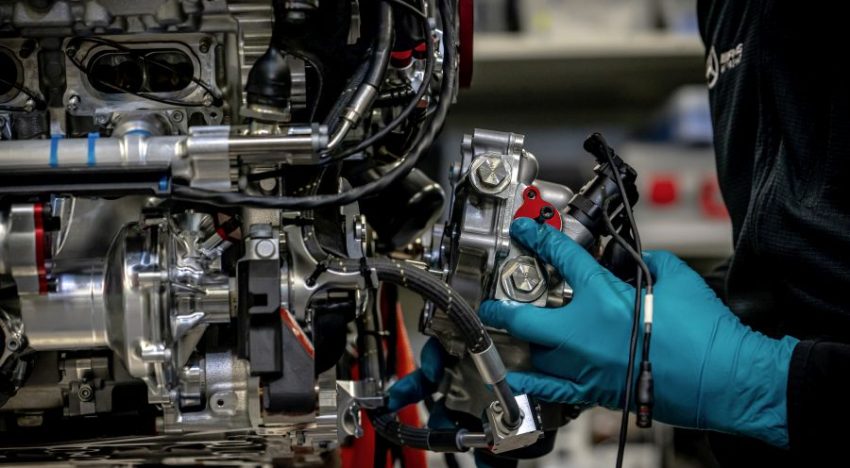

The Mercedes-AMG One is the second Mercedes supercar to be produced outside of Germany. The powertrain with its 1.6-litre turbocharged V6 engine and four electric motors is produced in Briworth, UK by the experts from Mercedes-AMG High Performance Powertrains who are also responsible for producing the engines for the Mercedes-AMG Petronas F1 team.

The Mercedes-AMG One is assembled in Coventry, UK, by AMG together with partner Multimatic. A small series production facility has been built for this purpose.

All production is carried out manually on the production line with 16 assembly and test stations. Some sub-systems are pre-assembled and tested and then disassembled again and reassembled into the final model. For example, the doors, bonnet and tailgate are pre-assembled, then disassembled, hand-painted and reassembled on the final car.

Before the propulsion system consisting of the 1.6 litre turbocharged V6 engine, the high voltage battery and the four electric motors is fitted, it is extensively tested on the test bench in Brixworth using the same test procedure as in case of F1 car.

In the press release, Mercedes gives details of what each of the 16 assembly stations does:

Stations 1-4: assembly of mechanical parts, essential powertrain components and low-voltage components including electrical installation.

Stations 5-6: assembly of the high voltage battery, testing of the thermal engine and electrical components

Station 7: interior assembly

Station 8: installation of exterior panels and doors

Station 9: hood and tailgate installation.

Station 10: completion of body assembly

Station 11: fitting the wheels and floor.

Step 12: adjust wheels and headlights.

Station 13: roller dynanometer testing of the car in all driving modes.

Station 14: Four post NVH test, fine tuning if is needed.

Station 15: Rain test

Station 16: Final technical and visual inspection.

50 specialists work on each car and the production process uses the Inudstry 4.o software also used by Mercedes-AMG in Affalterbach. At the end, a factory test driver tests each car on the track after which it is loaded into a closed truck and transported to the Affalterbach site. Here each customer is invited to take over the car, not before they are instructed with a detailed technical briefing.

Mercedes has announced the first deliveries in the second part of 2022. We have more detailed informations and we have learned that first deliveries will begin in September 2022. One of the 275 future owners of the car is the former tennis player and well know business man Ion Tiriac.